The other 2 points of sway control are created by the steel-on-steel friction that occurs when the spring bars slide along the L-brackets that are mounted on the trailer tongue. When the trailer moves forward or backward, or side to side, it causes the brackets to rub against the spring bars, creating friction.

The resistance created by this action limits the movement of the brackets, thus preventing further side-to-side movement of the trailer. Shop Equal-i-zer weight distribution systems.

How to Install Sway Bars on Reese Weight Distribution | www.mfarrow.com

The SwayPro offers 4 points of built-in sway control. Within the head assembly the trunnions are designed to hold the spring bars securely in position, placing just enough tension on them to cause them to constantly force your trailer to remain in line. At the other end of this weight distribution system, the rotating brackets ensure that the lift chains are pulled as taut as possible. This limits the movement of the spring bars so that they can exert more force on your trailer to effectively keep it from shifting side-to-side.

- Table Of Contents?

- ?

- a radiometric dating technique uses the decay of u 238 to pb 206.

- dating courtship engagement and marriage.

- Common Weight Distribution and Sway Control Questions | www.mfarrow.com!

- Blue ox sway bar hookup - La Valdichiana!

- what does it mean when you dream you are dating a celebrity.

In addition to creating points of sway control, the SwayPro's rotating latch brackets are supremely easy to use. All you have to do to attach the spring bars to the trailer frame is insert the lift chain into the bracket slot and rotate the bracket with the included wrench until the lock pin engages. Shop Blue Ox weight distribution systems. The Husky Center Line heavy-duty weight distribution system uses tension in the system head and friction at the frame brackets to prevent trailer sway. The bars are uniquely shaped - round at the head and tapering down to a wide, flat shape at the bracket end - to be rigid enough to effectively distribute weight and flexible enough to ensure a smooth ride.

The bars are made of hardened, heat-treated steel. Shop Husky weight distribution systems. The Curt TruTrack has spring-loaded ball bearings that are built into detents in the system head. They allow the TruTrack to self-adjust and self-center during crosswinds and sudden swerving. In addition, the spring bar mounting brackets create friction to resist movement of the spring bars to further deter sway. Together, these create the 4 points of sway control for this system. The system head has 5 preset positions to choose from, making it fast and easy to get the right tilt for your setup.

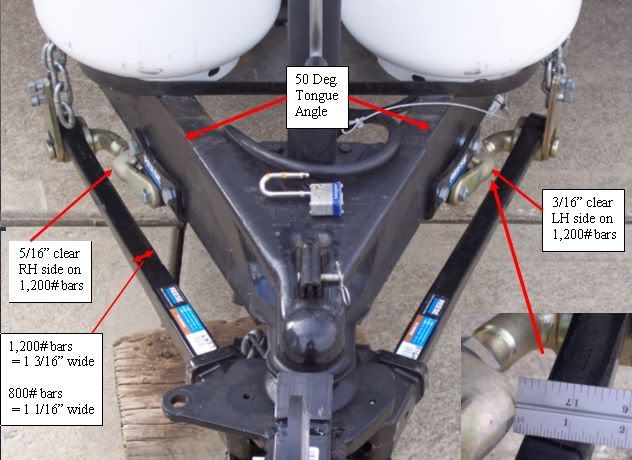

How to Install Sway Bars on Reese Weight Distribution

Shop Curt TruTrack weight distribution systems. This high-performance weight-distributing hitch offers spring bars with excellent flex, ensuring the load is always evenly distributed, even on rough terrain. The dual cam system keeps the trailer in a straight line behind the tow vehicle. This specially designed system uses unique sliding devices called cams to suspend the spring bars of the weight distribution system. One end of each cam bolts onto your trailer's frame, and the other end attaches to the lift bracket via the lift chain.

The hooked ends of the spring bars then sit in the cams where their shape helps prevent sway while allowing enough movement for free, easy interaction between your trailer and your tow vehicle. Shop Reese Strait-Line weight distribution systems.

In addition to the Class III, IV or V trailer hitch on your vehicle, a weight distribution system is made up of the ball mount, spring bars and trailer-frame-mounted brackets. The ball mount is composed of 2 pieces: The hitch ball is often sold separately. Trailer hitches are classified based on weight-carrying capabilities.

Not all Class III hitches are designed to be used with weight distribution systems, though. Always check the weight rating label that is on the trailer hitch. This sticker lists two capacities: If nothing is listed for weight distributing, then a weight distribution system cannot be used. The weight distribution shank is the piece that slides into your trailer hitch and provides an attachment point for the weight distribution head assembly.

Shanks are available in many different lengths, drops and rises to fit multiple applications.

- Common Weight Distribution and Sway Control Questions.

- hook up site korea.

- Product Page this Question was Asked From?

- chicago dating site.

- Featured Help Information?

This is to ensure that your trailer is level with your tow vehicle when it is hooked up. Standard shanks - those included with weight distribution systems - typically have a maximum rise of about 6" and a maximum drop of approximately 2". Consult the description of the product you are considering to get the maximum rise and drop specific to that part. Weight distribution systems are available both with and without the shank. If you need a shank with a rise or drop that is greater than the standard measurements, purchase a system that does not include a shank and then choose the shank that you need separately.

The weight distribution head assembly attaches to the channel or bolt holes along the shank and provides mounting points for the hitch ball and the spring bars. The weight distribution head assembly provides a place to mount the hitch ball that is used for trailer hookup. In addition, many weight distribution heads have built-in platforms for mounting bar-style friction sway controls. A bar-style sway control mounts to a smaller ball on the side of the weight distribution head. Some heads only have ball holes for a right-side attachment. Others, like the one pictured, have dual platforms so that you can mount a sway control on either side or both sides of your trailer.

The heads of weight distribution systems come in different styles - heads for round spring bars and heads for trunnion spring bars. The round-style bars slide up into the head and are held in place with clips. The trunnion-style bars slide into the head from the side or the back. To achieve proper positioning for a weight distribution system, you may have to adjust the tilt of the head assembly.

What Is Weight Distribution?

There are a few ways to do this, depending on the system you choose. The traditional washer-style adjustment method lets you adjust the tilt by sliding washers onto a spacer rivet and then inserting the rivet into the head assembly. To increase the angle, add a washer. To reduce the angle, remove a washer. Accessing the pin and washers can be a bit tedious, but this typically has to be done at initial setup only or if you switch trailers.

Serrated washers make adjusting the tilt of the weight distribution head a snap. An improvement over the standard pin-and-washer - or traditional washer-style - method, this method lets you fine-tune leverage without having to access a rivet inside the head. The serrated-washer system lets you easily loosen, adjust and tighten a single washer and nut on either side of the head for simple, secure positioning.

This type of system is most often found on Reese trunnion-style weight distribution hitches. The easy-to-use, block-style washer system features a uniquely shaped washer that can be rotated and positioned between blocks on the weight distribution head. Each side of the hexagonal washer is numbered to provide reference points should you need to adjust your system if you switch it between different tow vehicles.

Sway bar hook up

There's no need to use a difficult-to-access pin to obtain your desired tilt. This system is common on Reese round-bar-style weight distribution hitches. The Curt TruTrack eliminates traditional washer design and simplifies the tilt adjustment process by giving you 5 preset adjustment positions to choose from.

As a result, you can quickly and conveniently achieve the proper tilt without ever needing to disassemble the head or keep track of washers. To fine-tune the system, you work through the 5 preset positions in order until the correct tilt is achieved. Then you install and tighten the shank bolt.

Spring bars are responsible for transferring the load that pushes down on the rear of your vehicle when you are towing to the axles on both your tow vehicle and trailer. By applying leverage to your towing setup, these bars are responsible for distributing the weight in a complete weight distribution setup.

When Is Weight Distribution Needed?

Typically, there are 2 types of spring bars - round and trunnion. Some manufacturers have specialized spring bars.

Round bars slide up into the weight distribution head and are held in place with clips.